Teaching Pedagogy

Mechanical Engineering education is designed to provide students with a strong foundation in fundamental concepts, hands-on experience, and industry exposure. The pedagogy incorporates various teaching methodologies to ensure effective learning:

- Lecture-Based Learning

- Conceptual learning through interactive lectures covering thermodynamics, fluid mechanics, machine design, manufacturing processes, etc.

- Multimedia tools, real-world case studies, and problem-solving sessions to enhance understanding.

- Laboratory and Experimental Learning

- Practical exposure through labs for material testing, fluid mechanics, heat transfer, dynamics, and CNC machining.

- Experiments that reinforce theoretical concepts and develop hands-on skills.

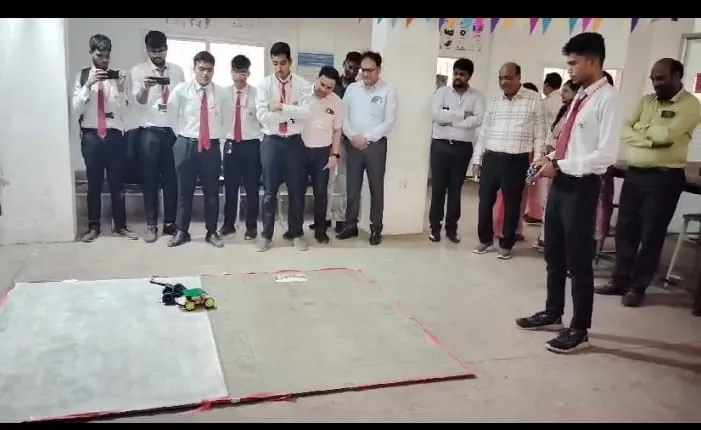

- Project-Based and Problem-Based Learning (PBL)

- Encouraging students to work on real-world engineering problems through individual and group projects.

- Design and development of mechanical systems to enhance problem-solving skills.

- Industry-Integrated Learning

- Industrial visits, guest lectures, and live projects in collaboration with industries.

- Exposure to the latest advancements in automation, robotics, and manufacturing.

- Computer-Aided Learning and Simulations

- Training in software like AutoCAD, SolidWorks, CATIA, ANSYS, MATLAB, and CFD for design and analysis.

- Simulating mechanical components and processes to enhance technical understanding.

- Interdisciplinary and Emerging Technology Learning

- Integration of IoT, Artificial Intelligence, and Data Analytics in mechanical systems.

- Exposure to smart manufacturing, Industry 4.0, and sustainable engineering practices.

- Research-Oriented Learning

- Encouragement for innovation, patent filing, and publishing research papers.

- Participation in technical competitions, hackathons, and SAE/Baja events.

- Entrepreneurship and Innovation-Based Learning

- Incubation support for startups and product development in mechanical engineering.

- Encouragement of students to develop their own innovations and business models.

- Sustainable and Ethical Engineering Education

- Focus on environmentally friendly mechanical solutions.

- Emphasis on ethical and responsible engineering practices.

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)